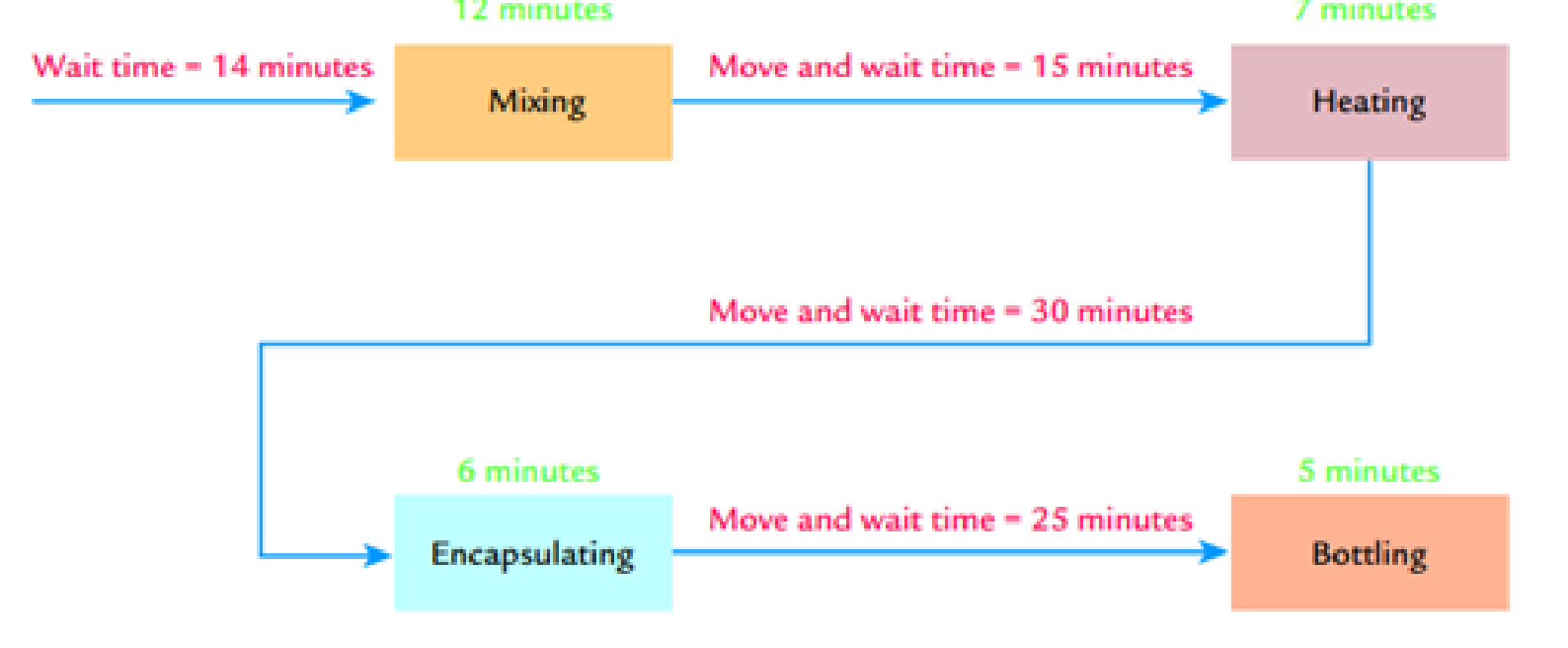

Erba Inc. has the following departmental layout for producing an herbal supplement:

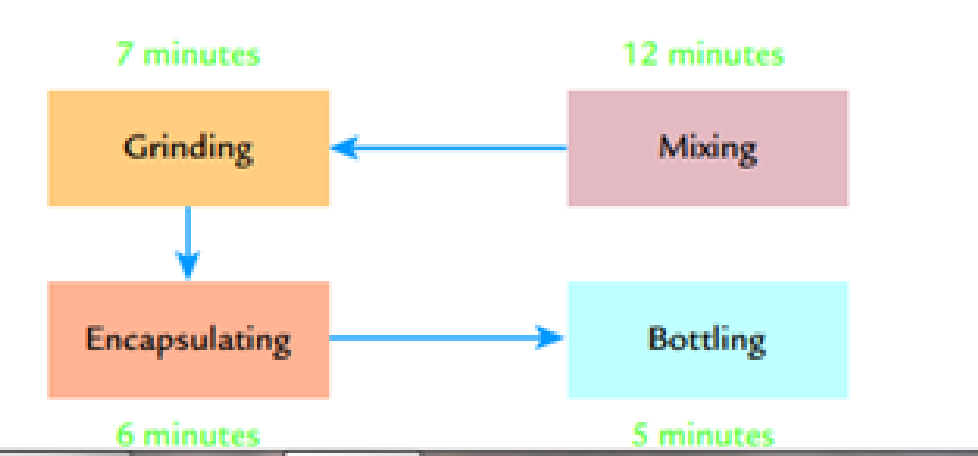

After a detailed study, the head of the plant’s industrial engineering department recommended that the following cellular manufacturing layout replace the current departmental structure:

Required:

- 1. Calculate the time required to produce a batch of 12 bottles using a batch processing departmental structure.

- 2. Calculate the time to process 12 units using cellular manufacturing.

- 3. How much manufacturing time will the cellular manufacturing structure save for a batch of 12 units?

- 4. How many units can the cell produce per hour, assuming the cell is producing on a continuous basis?

- 5. What must happen so that the cell can produce 12 units per hour, assuming the cell produces on a continuous basis?

1.

Compute the time taken to produce 12 units in case of a traditional manufacturing layout.

Answer to Problem 43E

Total time taken is 444 minutes.

Explanation of Solution

Traditional manufacturing layout:

In a traditional manufacturing layout, each process is undertaken within a separate department. In this layout large batches are processed, incurring significant wait time and move time.

Computation of time taken by 12 units:

| Particulars | Minutes |

| Wait time | 14 |

| Add: Time taken in mixing department | 144 |

| Add: Move and wait time between mixing and heating department | 15 |

| Add: Time taken in heating department | 84 |

| Add: Move and wait time between heating and encapsulating department | 30 |

| Add: Time taken in encapsulating department | 72 |

| Add: Move and wait time between encapsulating and bottling department | 25 |

| Add: Time taken in bottling department | 60 |

| Total time | 444 |

Table (1)

Therefore, total time taken is 444 minutes.

2.

Compute the time taken to produce 12 units in case of a cellular manufacturing layout.

Answer to Problem 43E

Total time taken to produce 12 units in cellular manufacturing is 162 minutes.

Explanation of Solution

Computation of time taken by 12 units:

| Particulars | Minutes |

|

Time taken by first unit | 30 |

|

Time taken by second unit | 42 |

|

Time taken by twelfth unit. | 162 |

| Total time | 162 |

Table (2)

Therefore, total time taken to produce 12 units in cellular manufacturing is 162 minutes.

3.

Compute the time saved in cellular manufacturing structure for a batch of 12 units.

Answer to Problem 43E

Time saved in cellular manufacturing structure for a batch of 12 units is 282 minutes.

Explanation of Solution

Computation of time saved in cellular manufacturing:

| Particulars | Minutes |

| Total time taken in traditional/batch processing | 444 |

| Total time taken in cellular processing | 162 |

| Time saved | 282 |

Table (3)

Therefore, time saved in cellular manufacturing structure for a batch of 12 units is 282 minutes.

4.

Compute the production rate in case of continuous operating.

Answer to Problem 43E

Production rate is 12 minutes per unit or 5 units per hour.

Explanation of Solution

There is a total of 12 minutes of waiting for each unit. In case, cell operates continuously and steadily, one unit would be produced after every 12 minutes. Therefore, it would take 144 minutes

Therefore, production rate is 12 minutes per unit or 5 units

5.

Explain the changes to be made so that the cell can produce 12 units per hour in case, cell produces on a continuous basis.

Answer to Problem 43E

Time taken by bottleneck activity should be 5 minutes.

Explanation of Solution

Computation of revised time taken by bottleneck activity:

Substitute 60 for minutes in an hour and 12 for the number of units required to be produced in the above formula.

The incremental time taken by each unit should be 5 minutes, in order to produce 12 units per hour on an incremental basis. For this, maximum time taken by any process should be 5 minutes.

Therefore, to produce 12 units per hour, time taken by bottleneck activity should be 5 minutes.

Want to see more full solutions like this?

Chapter 13 Solutions

Managerial Accounting: The Cornerstone of Business Decision-Making

- Anderson Company has the following departmental manufacturing structure for one of its products: After some study, the production manager of Anderson recommended the following revised cellular manufacturing approach: Required: 1. Calculate the total time it takes to produce a batch of 20 units using Andersons traditional departmental structure. 2. Using cellular manufacturing, how much time is saved producing the same batch of 20 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate? 3. What if the processing times of molding, welding, and assembly are all reduced to six minutes each? What is the production rate now, and how long will it take to produce a batch of 20 units?arrow_forwardBienestar Inc., has the following departmental structure for producing a well-known multivitamin: A consultant designed the following cellular manufacturing structure for the same product: The times above the processes represent the time required to process one unit of product. Required: 1. Calculate the time required to produce a batch of 15 bottles using a batch-processing departmental structure. 2. Calculate the time to process 15 units using cellular manufacturing. 3. How much manufacturing time will the cellular manufacturing structure save for a batch of 15 units?arrow_forwardGumbrecht Company has the following departmental manufacturing layout for one of its plants: A consulting firm has recommended a value stream with the following manufacturing cell: Required: 1. Calculate the total time it takes to produce a batch of 20 units using the traditional departmental manufacturing layout. 2. Using cellular manufacturing, how much time is saved producing the same batch of 20 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate? 3. Assume the processing time of Casting is reduced to 9 minutes, while the times of the other processes stay the same. What is the production rate now, and how long will it take to produce a batch of 20 units if the cell is in a continuous production mode?arrow_forward

- A dedicated pharmaceutical plant uses the theory of constraints and has three processes: Mixing, Encapsulating, and Packaging. For Mixing, sufficient materials are released to produce 4,000 packages of product per day. Encapsulating has a buffer inventory of 8,000 units (work in process from Mixing). Packaging produces 4,000 units per day. Which of the three processes sets the production rate of 4,000 units per day? a. The Mixing Department b. The Encapsulating Department c. The Packaging Department d. Cannot be determinedarrow_forwardMabbut Company has the following departmental manufacturing layout for one of its plants: A consulting firm recommended a value stream with the following manufacturing cell: Required: 1. Calculate the total time it takes to produce a batch of 10 units using the traditional departmental manufacturing layout. 2. Using cellular manufacturing, how much time is saved producing the same batch of 10 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate? 3. Assume the processing time of Welding is reduced to 6 minutes, while the times of the other processes stay the same. What is the production rate now, and how long will it take to produce a batch of 10 units if the cell is in a continuous production mode?arrow_forwardWilliams Optical Inc. is considering a new lean product cell. The present manufacturing approachproduces a product in four separate steps. The production batch sizes are 45 units. The processtime for each step is as follows: Process Step 1 5 minutesProcess Step 2 8 minutesProcess Step 3 4 minutesProcess Step 4 3 minutes The time required to move each batch between steps is 5 minutes. In addition, the time tomove raw materials to Process Step 1 is also 5 minutes, and the time to move completed unitsfrom Process Step 4 to finished goods inventory is 5 minutes.The new lean layout will allow the company to reduce the batch sizes from 45 units to 3 units.The time required to move each batch between steps and the inventory locations will be reducedto 2 minutes. The processing time in each step will stay the same.Determine the value-added, non-value-added, and total lead times, and the value-added ratio under the (a) present and (b) proposed production approaches. Round percentages to one…arrow_forward

- (GGI) manufactures lawn fertilizer. Because of the product’s very high quality, GGI often receives special orders from agricultural research. For each type of fertilizer sold, each bag is carefully filled to have the precise mix of components advertised for that type of fertilizer. GGI’s operating capacity is 26,000 one-hundred-pound bags per month, and it currently is selling 24,000 bags manufactured in 24 batches of 1,000 bags each. The firm just received a request for a special order of 7,000 one-hundred-pound bags of fertilizer for $150,000 from APAC, a research organization. The production costs would be the same, but there would be no variable selling costs. Delivery and other packaging and distribution services would cause a one-time $2,500 cost for GGI. The special order would be processed in two batches of 3,500 bags each. (No incremental batch-level costs are anticipated. Most of the batch-level costs in this case are short-term fixed costs, such as salaries and…arrow_forwardGreen Grow Incorporated (GGI) manufactures lawn fertilizer. Because of the product’s very high quality, GGI often receives special orders from agricultural research groups. For each type of fertilizer sold, each bag is carefully filled to have the precise mix of components advertised for that type of fertilizer. GGI’s operating capacity is 22,000 one-hundred-pound bags per month, and it currently is selling 20,000 bags manufactured in 20 batches of 1,000 bags each. The firm just received a request for a special order of 5,000 one-hundred-pound bags of fertilizer for $130,000 from APAC, a research organization. The production costs would be the same, but there would be no variable selling costs. Delivery and other packaging and distribution services would cause a one-time $2,500 cost for GGI. The special order would be processed in two batches of 2,500 bags each. (No incremental batch-level costs are anticipated. Most of the batch-level costs in this case are short-term fixed costs,…arrow_forwardIngles Corporation is a manufacturer of tables sold to schools, restaurants, hotels, and other institutions. The table tops are manufactured by Ingles, but the table legs are purchased from an outside supplier. The Assembly Department takes a manufactured table top and attaches the four purchased table legs. It takes 16 minutes of labor to assemble a table. The company follows a policy of producing enough tables to ensure that 40 percent of next months sales are in the finished goods inventory. Ingles also purchases sufficient materials to ensure that materials inventory is 60 percent of the following months scheduled production. Ingless sales budget in units for the next quarter is as follows: Ingless ending inventories in units for July 31 are as follows: Required: 1. Calculate the number of tables to be produced during August. 2. Disregarding your response to Requirement 1, assume the required production units for August and September are 2,100 and 1,900, respectively, and the July 31 materials inventory is 4,000 units. Compute the number of table legs to be purchased in August. 3. Assume that Ingles Corporation will produce 2,340 units in September. How many employees will be required for the Assembly Department in September? (Fractional employees are acceptable since employees can be hired on a part-time basis. Assume a 40-hour week and a 4-week month.) (CMA adapted)arrow_forward

- Jacson Company produces two brands of a popular pain medication: regular strength and extra strength. Regular strength is produced in tablet form, and extra strength is produced in capsule form. All direct materials needed for each batch are requisitioned at the start. The work orders for two batches of the products are shown below, along with some associated cost information: In the Mixing Department, conversion costs are applied on the basis of direct labor hours. Budgeted conversion costs for the department for the year were 60,000 for direct labor and 190,000 for overhead. Budgeted direct labor hours were 5,000. It takes one minute of labor time to mix the ingredients needed for a 100-unit bottle (for either product). In the Bottling Department, conversion costs are applied on the basis of machine hours. Budgeted conversion costs for the department for the year were 400,000. Budgeted machine hours were 20,000. It takes one-half minute of machine time to fill a bottle of 100 units. Required: 1. What are the conversion costs applied in the Mixing Department for each batch? The Bottling Department? 2. Calculate the cost per bottle for the regular and extra strength pain medications. 3. Prepare the journal entries that record the costs of the 12,000 regular strength batch as it moves through the various operations. 4. Suppose that the direct materials are requisitioned by each department as needed for a batch. For the 12,000 regular strength batch, direct materials are requisitioned for the Mixing and Bottling departments. Assume that the amount of cost is split evenly between the two departments. How will this change the journal entries made in Requirement 3?arrow_forwardVollmer Manufacturing makes three components for sale to refrigeration companies. The components are processed on two machines: a shaper and a grinder. The times (in minutes) required on each machine are as follows: The shaper is available for 120 hours, and the grinder for 110 hours. No more than 200 units of component 3 can be sold, but up to 1,000 units of each of the other components can be sold. In fact, the company already has orders for 600 units of component 1 that must be satisfied. The profit contributions for components 1, 2, and 3 are 8, 6, and 9, respectively. a. Formulate and solve for the recommended production quantities. b. What are the objective coefficient ranges for the three components? Interpret these ranges for company management. c. What are the right-hand-side ranges? Interpret these ranges for company management. d. If more time could be made available on the grinder, how much would it be worth? e. If more units of component 3 can be sold by reducing the sales price by 4, should the company reduce the price?arrow_forwardTaylor Company produces two industrial cleansers that use the same liquid chemical input: Pocolimpio and Maslimpio. Pocolimpio uses two quarts of the chemical for every unit produced, and Maslimpio uses five quarts. Currently, Taylor has 6,000 quarts of the material in inventory. All of the material is imported. For the coming year, Taylor plans to import 6,000 quarts to produce 1,000 units of Pocolimpio and 2,000 units of Maslimpio. The detail of each products unit contribution margin is as follows: Taylor Company has received word that the source of the material has been shut down by embargo. Consequently, the company will not be able to import the 6,000 quarts it planned to use in the coming years production. There is no other source of the material. Required: 1. Compute the total contribution margin that the company would earn if it could import the 6,000 quarts of the material. 2. Determine the optimal usage of the companys inventory of 6,000 quarts of the material. Compute the total contribution margin for the product mix that you recommend. 3. Assume that Pocolimpio uses three direct labor hours for every unit produced and that Maslimpio uses two hours. A total of 6,000 direct labor hours is available for the coming year. a. Formulate the linear programming problem faced by Taylor Company. To do so, you must derive mathematical expressions for the objective function and for the materials and labor constraints. b. Solve the linear programming problem using the graphical approach. c. Compute the total contribution margin produced by the optimal mix.arrow_forward

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,

Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning, Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub