Concept explainers

Suppose production requirements in Solved Problem 9.2 (see page 383) increase and require a reduction in cycle time from 3 minutes to 7 minutes. Balance the line once again, using the new cycle time. Note that it is not possible to combine task times so as to group tasks into the minimum number of workstations. This condition occurs in actual balancing problems fairly often.

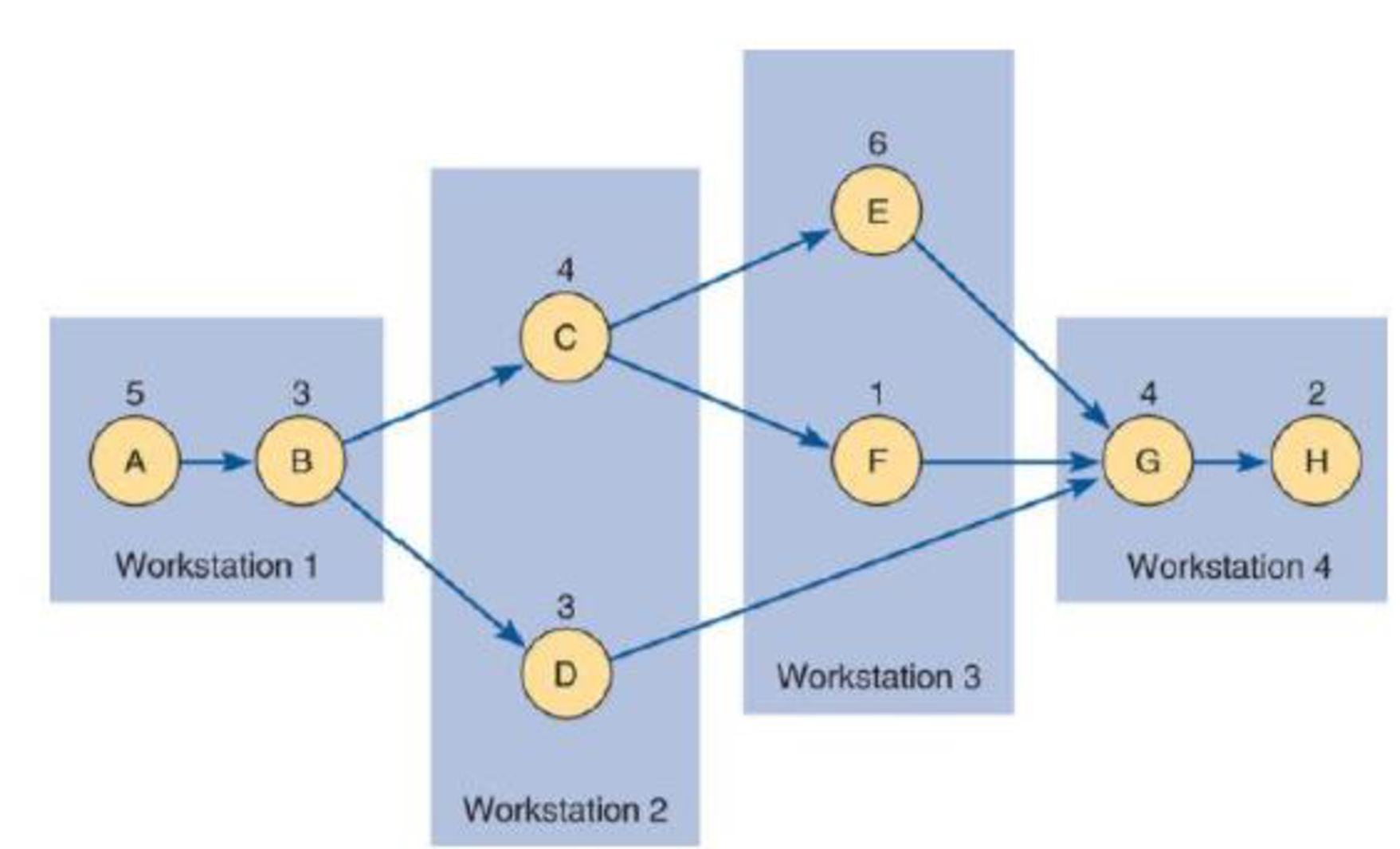

The assembly line whose activities are shown in Figure 9.18 has an 8-minute cycle time. Draw the precedence graph and find the minimum possible number of one-person workstations. Then arrange the work activities into workstations so as to balance the line. What is the efficiency of your line balance?

| TASK | PERFORMANCE TIME (MINUTES) | TASK MUST FOLLOW THIS TASK |

| A | 5 | — |

| B | 3 | A |

| C | 4 | B |

| D | 3 | B |

| E | 6 | C |

| F | 1 | C |

| G | 4 | D,E,F |

| H | 2 | G |

| 28 |

Figure 9.18 Four-Station Solution to the Line-Balancing Problem

Solution

The theoretical minimum number of workstations is:

The precedence graph and one good layout are shown in Figure 9.18:

Want to see the full answer?

Check out a sample textbook solution

Chapter 9 Solutions

OPERATIONS MGMT.(EBOOK)W/MYOMLAB>IC<

- A firm that produces electric golf carts has just received an order for 200 carts, which must be ready for delivery at the start of week 8. Information concerning the product structure, lead times, and quantities on hand is shown in the following table. Use this information to do each of the following: a. Construct an assembly time chart in Excel.arrow_forwardAn assembly plant for the Blood Pressure RX, a portable blood pressure device, has 400 minutes available daily in the plant for the device, and the average demand is 80 units per day. Final assembly requires 6 separate tasks. Information concerning these tasks is given in the following table. Task Performance Time (minutes) Task Must Follow Task Listed Below A 4 - B 1 - C 1 A, B D 3 C E 4 D F 2 E b) Given the demand, what is the cycle time for this operation? The cycle time for this operation is enter your response here minutes/unit (enter your response as a whole number). c) What is the theoretical minimum number of workstations? The theoretical minimum number of workstations is enter your response here stations (enter your response as a whole number and, if your unrounded answer includes decimal values,…arrow_forwardAn assembly line is to operate eight hours per day with a desired output of 250 units per day. The following table contains information on this product’s task times and precedence relationships: TASK TASK TIME (SECONDS) IMMEDIATE PREDECESSOR A 50 — B 20 A C 25 A D 35 A E 60 B, C F 60 C, D G 50 E, F H 90 G What is the required workstation cycle time to meet the desired output rate? Note: Round your answer to the nearest whole number. Balance this line using the longest task time. Note: Leave no cells blank - be certain to enter "0" wherever required. What is the efficiency of your line balance, assuming it is running at the cycle time determined in part b? Note: Round your answer to 1 decimal place.arrow_forward

- An assembly line is to operate eight hours per day with a desired output of 200 units per day. The following table contains information on this product’s task times and precedence relationships: TASK TASK TIME(SECONDS) IMMEDIATEPREDECESSOR A 60 — B 60 A C 50 A D 70 A E 30 B, C F 110 C, D G 70 E, F H 70 G b. What is the required workstation cycle time to meet the desired output rate? (Round your answer to the nearest whole number.) c. Balance this line using the longest task time. (Leave no cells blank - be certain to enter "0" wherever required.) d. What is the efficiency of your line balance, assuming it is running at the cycle time determined in part b? (Round your answer to 1 decimal place.)arrow_forwardKlassen Toy Company, Inc., assembles two parts(parts I and 2): Part I is first processed at workstation A for15 minutes per unit and then processed at workstation B for330 PART 2 DESIGNING OPERATIONS10 minutes per unit. Part 2 is simultaneously processed at workstationC for 20 minutes per unit. Workstations B and C feed theparts to an assembler at workstation D, where the two parts areassembled. The time at workstation Dis 15 minutes.a) What is the bottleneck of this process?b) What is the hourly capacity of the process?arrow_forwardAn assembly line is to operate eight hours per day with a desired output of 240 units perday. The following table contains information on this product’s task times and precedencerelationships: Task Task Time (Seconds) Immediate Predecessor A 60 — B 80 A C 20 A D 50 A E 90…arrow_forward

- Use the longest work element rule to balance the assembly line described in the following table and Figure so that it will produce 40 units per hour.a. What is the cycle time?b. What is the theoretical minimum number of workstations?c. Which work elements are assigned to each workstation?d. What are the resulting efficiency and balance delay percentages?e. Use the shortest work element rule to balance the assembly line. Do you note any changes in solution? Work Element Time (Sec) Immediate Predecessor(s) A B C D E F G H I J K 40 80 30 25 20 15 60 45 10 75 15 None A A B C B B D E,G F H,I,Jarrow_forwardAn assembly line must be designed to produce 40 containers per hour. The following data give the necessary information Table 1 TASK IMMEDIATE PREDECESSOR TASK TIME (sec) A None 60 B A 12 C B 35 D A 55 E D 10 F E 50 G F, C 5 Draw the precedence diagram. Compute the cycle time (in seconds) to achieve the desired output rate. What is the theoretical minimum number of stations? Assign the tasks to the workstation? What is the efficiency of the line? Calculate the idle timearrow_forwardAn assembly line must be designed to produce 50 packagesper hour. Th e following data in Table 10-17 give the necessaryinformation. (a) Draw a precedence diagram.(b) Compute the cycle time (in seconds) to achieve thedesired output rate.(c) What is the theoretical minimum number of stations?(d) Which work element should be assigned to whichworkstation?(e) What are the resulting effi ciency and balance delaypercentages?arrow_forward

- A company is setting up an assembly line to produce 90 units per hour. The table below identifies the work elements, times, and immediate predecessors. Work Element Time (Sec.) Immediate Predecessor(s) A 25 - B 18 A C 20 A D 5 B, C E 12 C F 8 E G 16 D, F H 12 G What cycle time is required to satisfy the required output? What is the theoretical minimum number of stations?arrow_forwardAlocal toy manufacturer is using a production line that runs 8 hours per day and produces a toy that requires a total of 7 tasks to be performed. The daily demand is 100 toys. Times of the tasks are 2.73, 2.01 201 2.13, 2.0, 2.61, 2.71 , and 2.95 minutes for A,B,C,D,E,F, and respectively. However, due to the nature of the product there are precedence rules that must be observed. Such that Task Adoes not need any predecessorsB requires task A to completed. To start task C and task Deach require task B to be completed. Task C must be completed prior to stating task E. Task F needs both task D and task Eto be completed. Finally, task G can start only once task Fis completed.Given we apply the most remaining tasks rule for balancing the assembly line with ties broken according to longest task time firstthe tasks that will be assigned to the SECOND workstation arearrow_forwardBalance the assembly line shown below for (a) a shift output of 60 pieces and (b) a shift output of 40 pieces. Assume an 8-hour shift, and use the rule: choose the assignable task with the longest processing time. Compute the line efficiency for each case. Fill in the table below for a shift output of 60 pieces. Break ties by choosing the lowest task number. If your answer is zero, enter "0". Round your answers to the nearest whole number. Workstation Tasks Total Time Idle Time 1 2 3 4 Total What is the assembly-line efficiency? Round your answer to one decimal place. % Fill in the table below for a shift output of 40 pieces. Break ties by choosing the lowest task number. If your answer is zero, enter "0". Round your answers to the nearest whole number. Workstation Tasks Total Time Idle Time 1 2 3 Total What is the assembly-line efficiency? Round your answer to one decimal place. %arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.