Concept explainers

Southern Toro Distributor, Inc.

The following conversation was held between Joe Melaney, general manager and owner of the Toro distributorship in Galveston, Texas, and his son Joe Jr.:

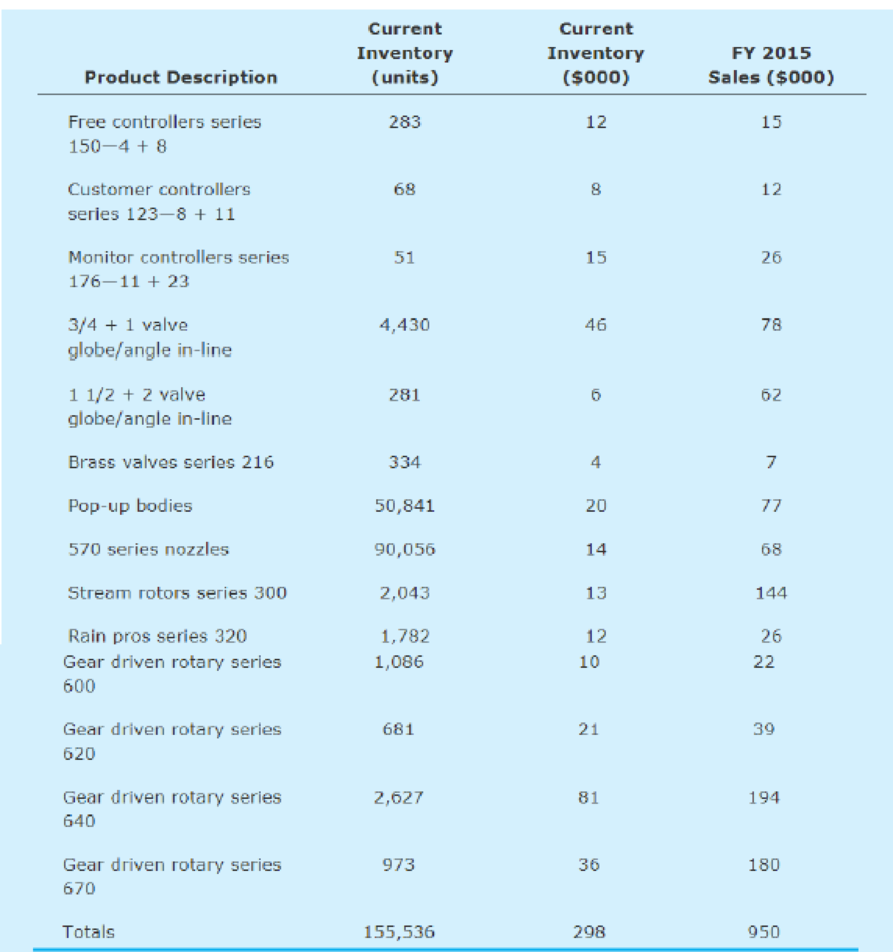

Joe: 1 called you in this morning to discuss the future of the company. I feel that you should be involved in more of the decision making around here because you will be taking over the company soon. Roger Kirk, the district sales manager from Toro, will be contacting us next week for our spring season order. We will need to order for the entire irrigation line at that time. (See Exhibit 1.)

EXHIBIT 1 Irrigation Products, Inc., current inventories, October 15, 2015.

Prepared for use in class discussion by Roger G. Schroeder, E.R. Kunde, and Sue Flach.

As you know, we have been undergoing a number of changes around the office. One of our major changes was acquiring the RyTech computer system. A computer run I received this morning combined with the upcoming order date started me thinking about the figures from the new computer. I was thinking back on the circumstances that led up to the purchase of the computer a year ago in October 2014. With the way costs are skyrocketing, I had to cut down on my inventory without cutting service. The RyTech representative said he could cut our inventory level by 30 percent, which sounded good enough for me. So I contracted with RyTech for the new software.

Max, our irrigation manager, swears by the numbers he gets out for order quantities. When this package was put into our computer, they (RyTech reps) said it was suitable for me, but I’m not sure that I can trust it. You remember the problems RyTech had getting it running. If they have problems like that, why should I trust it to tell me how to spend millions of my dollars?

Joe Jr: You mentioned that RyTech Installed the software for us. How did they select the decision rule used in determining the order quantities?

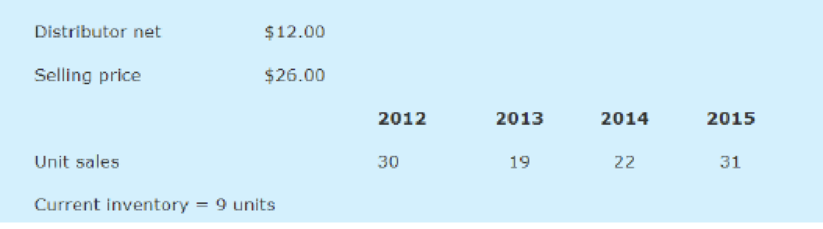

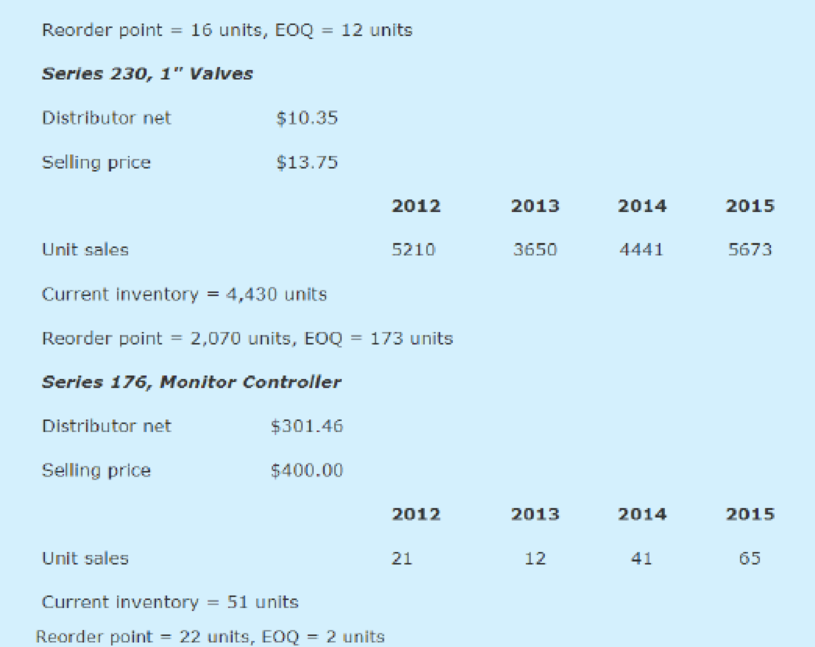

Joe; 1 can’t answer that. The consultants that came in told me the best way to determine the order quantities for my company was to use an economic order quantity (EOQ) and a reorder point for every item. (See Exhibit 2.) They said this was the best because we have three set order points during the year. I’m comfortable with the order point, but I’m not sure of the EOQ. I can tell you how the EOQ was made for us. They based it on the demand quantities from the past four years. (See Exhibit 3.) RyTech said that they did not see the need for any additional measures. They also said it would work very smoothly since it wasn’t necessary to change the EOQ once it was in.

EXHIBIT 2 Current computer system rules.

For order quantity size:*

A = cost of placing an order, $

D = annual demand in units

i = "interest rate" for holding inventory for a year as a proportion of the unit cost

c = unit cost of the item, $/unit

EOQ = economic order quantity

For reorder point:

R = average demand over the lead time + safety stock

R is the reorder point where an order for more stock is placed. Currently, a 12-week lead time is used for all items in setting the reorder point.

*The current computer system uses a carrying cost i = 30% (20% cost of capital, 5% obsolescence, and 5% storage cost) and an ordering cost of $10 per order.

EXHIBIT 3 Demand for fiscal years 2012-2015.

Part #1-7287 Timing Motor with Gear Service Assembly (for Monitor Controllers)

As I said earlier, I’m not sure of the EOQ. You know how I’ve depended upon my gut feel for the market in the past. I’ve always ordered parts based on past usage. Then I adjust the numbers according to how many golf courses I expect to be built or modified, and on the contractors’/installers’ comments on how they expect the spring to pane 464 go in terms of the number of installations. I also meet with friends in the building industry to see what they expect in terms of housing starts for the spring. My only other adjustments come if I think a particular product isn’t moving. I feel all goods should turn over at least three times a year. There are two items I am worried about at the present time because of that exact problem. One is the timing motor with gear service assembly (Part #1-7287), a low-volume service part carried for repair of monitor controllers, and the other is the Monitor Controller (Series 176) carried as an “insurance” end product for a few specialized customers. (See Exhibits 4 and 5 for detailed descriptions of the Monitor Controller and the Series 230 valve.)

EXHIBIT 4 Series 230 and 240—Automatic valves. 3/4" & 1" electric and hydraulic versions normally open, pin-type, 24 V.A.C. electric.

EXHIBIT 5 Series 170—Monitor II automatic controllers: 11 & 23 station, hydraulic and electric.

Joe Jr: I haven’t heard you mention the problem of running out of products. We have been having quite a problem with running out of the Series 230 1 inch valve, a high-demand part that we use all the time. How would you handle this in ordering? I know that we tend to disagree on what level of inventory should be held. I don’t think you are carrying a high enough inventory level on all parts to satisfy our customers. You have always said it is critical to the survival of the company that we have satisfied customers. I would tend to believe that this would require us to always have what our customers need on hand. The other problem I see resulting from stockouts is a loss of customers to our competitors. Any customer whose order we cannot fill will go to Rainbird, Weathermatic or Nelson. Any of these competitors could supply the customer with comparable equipment, and once the customers have made the change, how do we get them back?

Joe: I don’t have the storage capacity to carry enough inventory to protect ourselves from ever having a stockout. My philosophy has been that you can’t always satisfy the customer from on-hand inventory. But you better be able to satisfy them 90 percent of the time. When you don’t have it on hand, you can usually get it from another distributor. It usually is a fairly fast process because we fly the parts in. Too bad we can’t place rush orders with Toro, but they hold us to their standard ordering policy (Exhibit 6).

EXHIBIT 6 Irrigation division FY 2015-2016 stocking program, terms for southern distributors.

| Order Placement | Shipping Period | Dating Terms |

| 33% 2011 |

December and January | 1/2 May 15—net |

| Oct. 15-Oct. 30 | 1/2 June 15—net | |

| 33% 2012 Forecast | May and June | 1/2 Sept. 15—net |

| Feb. 15-Feb. 30 | 1/2 Oct. 15—net | |

| 33% 2012 Forecast | August and September | 1/2 Nov. 15-net |

| June 15-June 30 | 1/2 Dec. 15—net |

That reminds me, we have to face a possible stockout problem this year. When I was at the country club last week, George, the general manager at the club, was talking about the number of times their sprinkler system had failed. George mentioned that he had spoken to the board about replacing the system. While the board wouldn’t commit themselves until the annual meeting in December, George felt that it was going to be approved. If they installed the system, they wanted it ready to go by their annual tournament in early April. George said his first choice would be us if we could Page 467 supply the system within the time specified. This contract would be a highly profitable one. As you know, the course is 390 acres, and the entire system would have to be replaced. The replacement system would rely heavily on the use of the Series 230 valves.

Because of the size of the club’s system, I checked with my banker on the cost of financing. Bank notes were quoted at 9 percent. I’m not sure whether I should risk financing, so I’m looking at cutting back in the spare parts area, where a lot of our cash is tied up. I figured that we have 25 percent of our inventory just sitting in the warehouse collecting dust. Many of these items are used by only a few of our customers. If I decide against the latter technique, we would have to rent storage space to handle the parts for the golf course installation. When I checked into this yesterday, I was quoted a price of $3.27 per square foot per year for rented warehouse storage space.

To assist in determining the appropriate quantities and to get a little insight into the chance of the club’s installing the system, I called the National Weather Service this morning. They stated they expected the driest spring in five years. I’m not sure to what extent this would affect the sales of the irrigation products. To assist in determining the effect of weather on the sales, I have gone over the demand figures and the corresponding weather for the last five years. In 2012 and 2013 I greatly overstocked. During these years, the weather was extraordinarily wet and cloudy. During 2014 the reverse conditions existed. It was an abnormally dry season, and we stocked out of most of our goods. (See Exhibit 7 for more market characteristics.)

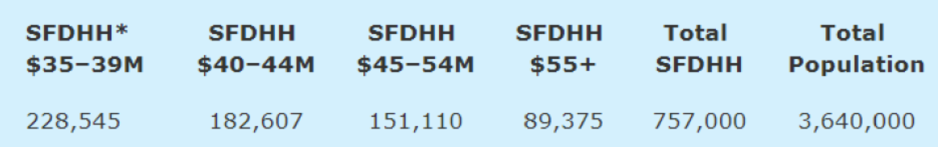

EXHIBIT 7 Galveston market information.

Number of golf courses: 158

Number of golf course holes: 2,259

Irrigation potential market (in purchases from Toro):†

| Small turf‡ | $403,830 | Number of cemeteries: 71 |

| Large turf‡ | 267,048 | Number of parks: 14 |

| Parts | 75,160 | Number of schools: 170 |

| Total | $846,038 |

*Number of persons living in single-family dwelling households (SFDHH).

† This is an estimate of the market size for Toro in the area.

‡ Small turf refers to residential installations while large turf refers to golf courses and other

commercial installations.

Joe Jr: With a business that is subject to the whims of nature, why do you stay in it? Is it really worth beating your head against the wall to get the kind of return on investment that we have been getting? Even though we get a 25 percent markup on all irrigation items, the results do not always appear on the bottom line. Maybe we could manage our inventories better and really make the business worthwhile. (See Exhibits 8, 9, and 10.)

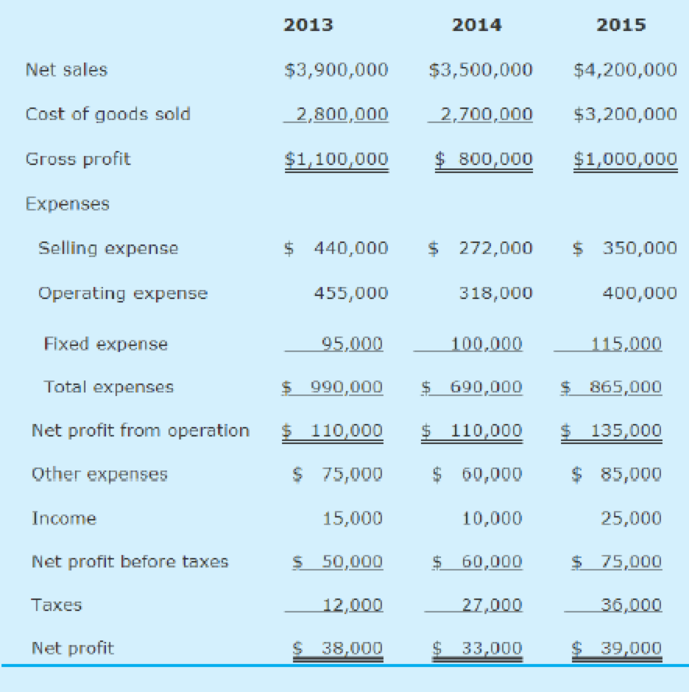

EXHIBIT 8 Income statement (fiscal years ending June 30).

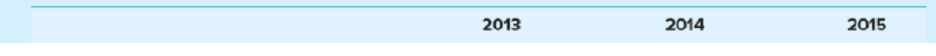

EXHIBIT 9 Balance sheet (fiscal years ending June 30).

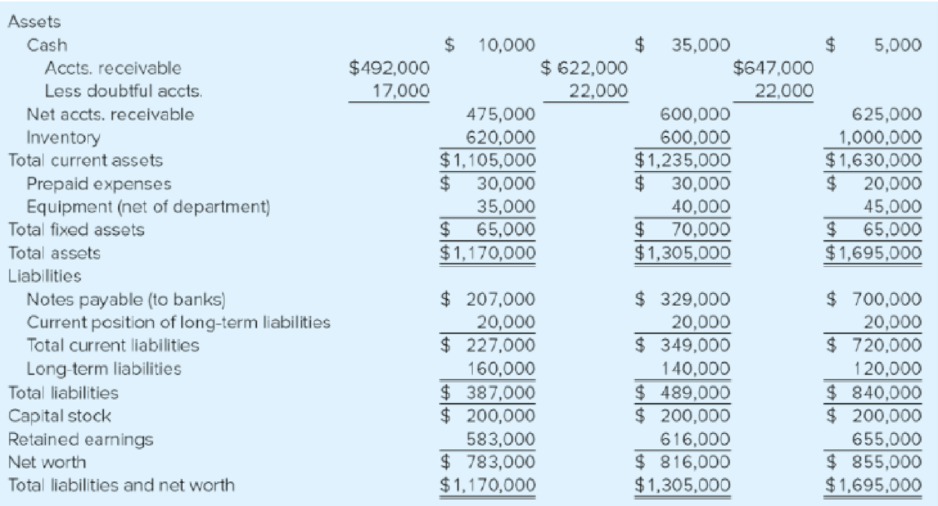

EXHIBIT 10 FY 2015 departmental analysis ($000).

Joe: In the past I stayed in this business because I started the business. It’s my baby. I felt a great deal of achievement from it. I’ve always planned to pass the company on to you and let you operate it. Now is the time for you to decide how you would run this company if you were in charge and if the return on investment is good enough for you to be satisfied. We also have to decide what to order from Roger Kirk when he arrives next week and what to do about using the RyTech system. I have another meeting now, but I would like to get back to this discussion later.

Discussion Questions

- 1. What would you recommend that Joe Jr. do, assuming he takes control of Southern Toro?

- 2. Evaluate the importance of inventory and inventory management of the Southern Toro distributorship for both irrigation products and spare parts. Should the inventory be cut back?

- 3. Evaluate the current inventory management system at Southern Toro. What inventory management system would you recommend?

Want to see the full answer?

Check out a sample textbook solution

Chapter CS Solutions

OPERATIONS MANAGMENT IN...-ACCESS

- As the manager overseeing Audiot and Co., you commenced the planning of audit work for a new client, Windo Ltd on June 3, 2021. Windo's financial year ends on June 30, 2021, and the audit is scheduled to be completed by August 15, 2021. The following information is relevant to the audit engagement: Windo specializes in providing repair services for motor vehicles and operates from five different locations. All inventory, sales, and purchasing systems are computerized, with each location maintaining its own system. The software used at each location is identical, as it was custom-developed by a reputable software house specifically for Windo. Data from all locations is consolidated monthly at the head office to generate management and financial accounts. Currently, you are in the process of planning the audit approach for Windo Ltd. One option under consideration is to modify Audiot & Co.'s audit software to interface with Windo's computerized inventory systems at each…arrow_forwardArthur (from Alabama) is a regional manager for a brand new textbook company, Big Law Publications (incorporated and principal place of business in Connecticut). Arthur’s job requires him to travel from school to school to show new casebooks to law professors. His assignment for the first week of February was to visit law schools in Alabama, Georgia, and Florida. While in Florida, Arthur goes to South Beach to have some fun. He ends up getting into a bar fight with Mel, a law student from Miami Beach, Florida. Arthur and Mel each blame the other for starting the fight. Question #1: Arthur (plaintiff) sues Mel (defendant) in Alabama state court for battery. Mel contests personal jurisdiction arguing that the Alabama court does not have jurisdiction over him. Will Mel prevail on his objection to personal jurisdiction? Why or why not? Question #2: Mel (plaintiff) sues Arthur (defendant) in Florida state court for battery. Arthur contests personal jurisdiction arguing that the Florida…arrow_forwardMs. Mary Mulenga and Ms. Joyce Hachiintu are second year students from the National Instituteof Public Administration pursuing a Bachelor of Arts in Public Administration. After writing their final second year semester exams, they decided to apply for internship at a named Non-Governmental Organization in Lusaka province so as to put theories into practice. The students are attached to Mr. Gleen, an American who happens to be the head of administration section. During departmental meetings, Mr. Glenn is seen to be advancing arguments which has made the students to have different perceptions about him. Ms. Mulenga views Mr. Gleen as a good person who knows his job very well, where as Ms. Hachiintu looks at him to be a person who is boastful and inexperienced and trying to seek attention. As an Organizational Behavior expert, explain the possibility of such a scenario.arrow_forward

- You are the Chief Executive Officer for NeverEnding Tyres Inc. You have the responsibility to secure a new distribution center where you own over 1000 hectares of land near the intended distribution center. For you, this could result to ____ a. the usual decision making problems of cost versus benefitb. a wonderful, ethical opportunity to make profitc. an ethical opportunity to move the distribution center to your hometownd. a conflict of interestarrow_forwardAs a student in the Principles of Management class of Union Ghana University, you are supposed to have experiential acquaintance so that you can be able to solve real life business problems after you graduate. To achieve this objective, the 2020 class has been divided into twelve groups; and each team works in a management capacity with twelve management consulting companies in the Volta Region. Kai Consulting - the firm that your group works with is a project management company that is into the development of a products and services and management consulting. This firm which has Twenty-five years’ experience in this business is the number one choice for all individuals and companies that want quality service. You have therefore observed that, many of the management practices have not developed quickly as situations in the business environment warrant. The bookkeeper confirmed this by saying in the last general meeting that a certain percentage of Kai’s profit margin is being lost…arrow_forwardConsider the following exchange between Rudy and Andi, residents of Detroit, Michigan, as they discuss the implication of working for a foreign owned corporation in their hometown. They are debating the threat of doing so to the vibrancy of the local economy and vitality of the community. Rudy: You have regularly expressed contempt for foreign car companies, saying they are just bad for our country. Indeed, as I think about it, I've heard you say on several occasions they are taking away jobs in your home town and ruining the local economy as well as the community. So, I'm quite surprised when I hear that you have applied for a job at the local Tataya Motors dealership. Applying to work for a Japanese car manufacturer, like Tataya Motors, means you don't really mind working for exactly the kind of foreign-owned company that you used to regularly criticize. In my opinion, and to be quite honest about it, it’s sure looks like you have compromised your principles just to get a job.…arrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning