Concept explainers

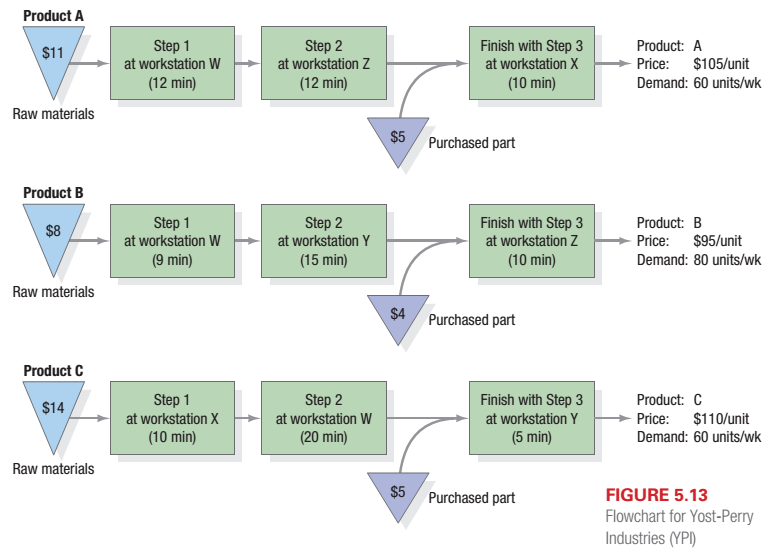

Yost-Perry Industries (YPI) manufactures a mix of afford able guitars

Want to see the full answer?

Check out a sample textbook solution

Chapter 5 Solutions

Operations Management: Processes and Supply Chains (12th Edition) (What's New in Operations Management)

- The manufacturing cycle efficiency for Sam Company when the processing time is seven hours and inspection, waiting, and move time are one hour each is: (round-off to 2 decimal places)arrow_forwardXYZ company provides labor and space for the manufacturing and assembly operations and stocking a variety of inventory items for production such as wire, cables, some electronic components, etc. XYZ company orders a variety of components and raw materials by contract. The company recently hired 100 part-time employees working four to six-hour shifts. Skilled employees must do several raw material conversions for packaging—there are currently three (3) such employees. The plant layout is a typical process layout - machines of similar types are located together. Each machine and employee must be scheduled over the day and the standard time period for planning is one (1) hour. Material handling is mainly done manually, although the company would like to consider conveyors or other automation to aid in automating their processes. XYZ company forecasts planned production for two (2) years on a rolling quarterly basis. Often, the customer changes the forecast, and these changes can occur…arrow_forwardA production process at Kenneth Day Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). A) is the bottleneck. b) The bottleneck time isminutes per unit (round your response to two decimal places). c) The throughput time of the overall system is enter your response here minutes (round your response to two decimal places). D) If the firm operates 8 hours per day, 20 days per month, the monthly capacity of the manufacturing process isunits (enter your response as a whole number).arrow_forward

- Please dont answer in image ormat,Do type. Canine Kennels Company (CKC) manufactures two different types of dog chew toys (A and B, sold in 1,000-count boxes) that are manufactured and assembled on three different workstations (W, X, and Y) using a small-batch process (see the figure below). Batch setup times are negligible. The flowchart denotes the path each product follows through the manufacturing process, and each product's price, demand per week, and processing times per unit are indicated as well. Purchased parts and raw materials consumed during production are represented by inverted triangles. CKC can make and sell up to the limit of its demand per week; no penalties are incurred for not being able to meet all the demand. Each workstation is staffed by a worker who is dedicated to work on that workstation alone and is paid $6 per hour. Total labor costs per week are fixed. Variable overhead costs are $3,500/week. The plant operates one 8-hour shift per day, or…arrow_forwardA firm uses a serial assembly system and needs answers to the following:a. An output of 900 units per shift (7.5 hours) is desired for a new processing system. The system requires the product to pass through four stations where the work content at each station is 30 seconds. What is the required cycle time for such a system?b. How efficient is your system with the cycle time you calculated?c. Station 3 changes and now requires 45 seconds to complete. What will need to be done to meet demand (assume only 7.5 hours are available)? What is the efficiency of the new system?arrow_forwardBill’s Barbershop has two barbers available to cut customers’hair. Both barbers provide roughly the same experience andskill, but one is just a little bit slower than the other. The pro-cess flow in Figure 5.9 shows that all customers go throughsteps B1 and B2 and then can be served at either of the twobarbers at step B3. The process ends for all customers atstep B4. The numbers in parentheses indicate the minutes ittakes that activity to process a customer. a. How long does it take the average customer to completethis process?b. What single activity is the bottleneck for the entireprocess?c. How many customers can this process serve in an hour?arrow_forward

- Steel City Juice is a local company that makes two kinds of juice: orange juice and apple juice.Demand for orange juice is 60 barrels/hr, while demand for apple juice is 40 barrels/hr. The company only has one machine to extract juice from raw fruit. The machine can extract orange juice at a speed of 150 barrels/hr, or apple juice at 120 barrels/hr. Switching from one type to the other requires 30 minutes cleanup time.Please provide a production schedule and an associated process flow diagram that (i) cycles repeatedly through the two kinds, (ii) meets the required demand, and (iii) minimizes the amount of inventory held. (Here it is assumed that the production machine runs 24 hours a day, 7 days a week ) and what is the maximum inventory level of orange juice?arrow_forwardA manufacturing plant has the process displayed below. The drilling operation occurs separately from and simultaneously with the sawing and sanding operations. The product only needs to go through one of the three one of the three assembly operations (the assembly operations are ‘parallel’). a) What is the bottleneck operation? b) What is the throughput time for the overall system? c) If the firm operates 10 hours a day, 21 days a month, what is the monthly and yearly capacity of the manufacturing process? d) Supposed that a second drilling machine is added, and it takes the same time as the original drilling machine. What is the new bottleneck time of the system? e) What is the new throughput time if the second drilling machine is added?arrow_forwardExplain what are the risks of automating a production process and what are the risks for a service process?arrow_forward

- A firm has redesigned its production process so that it now takes 10 hours for a unit to be made. Using the old process, it took 15 hours to make a unit. If the process makes one unit each hour on average and each unit is worth $1,500, what is the reduction in work-inprocess value?arrow_forwardA.J.’s Wildlife Emporium manufactures two unique birdfeed-ers (Deluxe and Super Duper) that are manufactured andassembled in up to three different workstations (X, Y, Z) us-ing a small batch process. Each of the products is producedaccording to the flowchart in Figure 5.14. Additionally, theflowchart indicates each product’s price, weekly demand,and processing times per unit. Batch setup times are neg-ligible. A.J. can make and sell up to the limit of its weeklydemand and there are no penalties for not being able to meetall of the demand. Each workstation is staffed by a workerwho is dedicated to work on that workstation alone and ispaid $16 per hour. The plant operates 40 hours per week,with no overtime. Overhead costs are $2,000 per week. Basedon the information provided, as well as the information con-tained in the flowchart, answer the following questions.a. Using the traditional method, which bases decisionssolely on a product’s contribution to profits and over-head, what is the…arrow_forwardA.J.’s Wildlife Emporium manufactures two unique birdfeed-ers (Deluxe and Super Duper) that are manufactured andassembled in up to three different workstations (X, Y, Z) us-ing a small batch process. Each of the products is producedaccording to the flowchart in Figure 5.14. Additionally, theflowchart indicates each product’s price, weekly demand,and processing times per unit. Batch setup times are neg-ligible. A.J. can make and sell up to the limit of its weeklydemand and there are no penalties for not being able to meetall of the demand. Each workstation is staffed by a workerwho is dedicated to work on that workstation alone and ispaid $16 per hour. The plant operates 40 hours per week,with no overtime. Overhead costs are $2,000 per week. Basedon the information provided, as well as the information con-tained in the flowchart, answer the following questions. a. Using the traditional method, which bases decisionssolely on a product’s contribution to profits and over-head, what is the…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,