Concept explainers

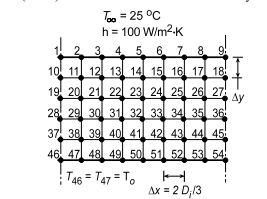

In a biomedical supplies manufacturing process, a requirement exists for a large platen that is to be maintained at

Considering the two-dimensional cross section of the platen shown in the inset, perform an analysis to determine the heating fluid temperature

Want to see the full answer?

Check out a sample textbook solution

Chapter 8 Solutions

Fundamentals of Heat and Mass Transfer

Additional Engineering Textbook Solutions

Vector Mechanics for Engineers: Dynamics

Foundations of Materials Science and Engineering

Engineering Mechanics: Dynamics (14th Edition)

Engineering Mechanics: Statics

Engineering Mechanics: Statics

Fox and McDonald's Introduction to Fluid Mechanics

- Two steel sheets of 1.5 mm thickness are spot welded in a lap joint with a current of 10,000 A for 0.15 second. Effective resistance of the joint is 150 micro ohm. The joint can be considered as a cylinder of 6 mm diam- eter and 2 mm height. If heat required for melting of 1 mm³ of steel is 10 J, heat loss (in percentage) to the surroundings isarrow_forwardAn eyed plate & pin is assembled as illustrated and are subjected to an opposing force of 10KN. The rod diameter & plate thickness is 6mm. The width of the plate is 20mm. A hole to which the pin is inserted is 8mm in diameter is located at the center of the plate. The plate is made of annealed SAE 1025 & the pin is high-heat oil quenched SAE 1095. (a) Determine if the assembly is safe to use; otherwise (b) Determine the safe load of the assembly.arrow_forwardIndustrial pipes One of the ways to keep a pipe warm is by means of a steam tracer, through which an electrical resistance is used around the pipe and in a helical shape throughout its diameter?arrow_forward

- 3. A steel pipeline 2”sch 40 (k = 45W/mK) contains saturated steam at 121.1oC. the line is insulated with 25.4 mm asbestos (k = 0.182W/mK). Assuming that the inside temperature of the metal wall is at 121.1oC and the outer surface of the insulation is at 26.7oC, calculate the heat loss for 30.5m of pipe.arrow_forward1ai. a steel bar 10.0 cm long is welded end-to-end to a copper bar 20.0 cm long. Both bars are insulated perfectly on their sides. Each bar has a square cross-section, 2.00 cm on a side. The free end of the steel bar is maintained at 1000C by placing it in contact with steam, and the free end of the copper bar is maintained at 00C by placing it in contact with ice. (ii)Calculate the temperature at the junction of the two bars. Suppose the two bars are now separated, with both ends of each of the bars now maintained at 1000C and 00C respectively, determine the total rate of heat flow in the two bars. b. If the total surface area of the human body is 1.20 m2 and the surface temperature is 300C, Determine the total rate of radiation of energy from the body. If the surroundings are at a temperature of 200C, calculate the net rate of heat loss from the body by radiation? c.You place a small piece of melting ice in your mouth. Eventually, the water all converts from ice at T1 = 32.000F to…arrow_forwardA cold storage room has a wall consists of an inside finish of 0.60 in cement plaster(k = 0.67), two layers of corkboard each 2.5 in thick (k = 0.03) and an outside layer of building tile. The value of U for the entire wall is 0.058, the internal air filmcoefficient is 1.65, the inner temperature is 23°F and the outside temperature is85°F. Calculate the heat flow through the unit wall area, Btu/hr.ft2A. 1.47 B. 2.47 C. 3.47 D. 4.47arrow_forward

- Question 1 A composite component is comprised of a tube and a concentric rod running inside it, both with a length of 1.5 meters. The tube is made of copper and has inner and outer diameters of 60 mm and 100 mm, respecti vely, a coefficient of thermal expansion and elastic modulus of 17 x10-6C and 117 GPa, respectively. The rod is made of aluminium with a diameter, coefficient of thermal expansion and elastic modulus of 50 mm, 23 x10-6C and 80 GPa, respectively. If the composite is exposed to a temperature rise of 120°C, determine: The sense and magnitude of the stresses induced in the composite if it is not restrained. 1.1 1.2 The sense and magnitude of the stresses induced in the composite ifit is partially restrained with an allowed free expansion of 0.3 mm.arrow_forwardObtain information about K - , E - , and R -type thermocouple wires. Write a brief report discussing their accuracy, temperature range of application, and in what application they are commonly employed.arrow_forward2. Connect an iron whose base plate is made of an aluminum alloy. Assumptions: • 85% of the heat generated in the resistance wires is transferred to the plate. • The thermal properties of the board are constant. • The heat transfer coefficient is constant and uniform over the entire surface. Properties: The density, specific heat and thermal diffusivity of the aluminum alloy plate are p= 2770 kg / m', cp = 875 kJ / kg. ° C and a = 7.3 x 10-5 m2 / s. Data: L plate = 0.005m, Plate = 0.03m?, Device nominal power = 1kW, Tar = 22°C a) How long does it take for the plate temperature to reach 140°C? Assuming the plate temperature is uniform at all times. b) The effects of the heat transfer coefficient and the final plate temperature on the time it takes for the plate to reach this temperature should be investigated. Plot h × t and Tplate X t.arrow_forward

- Problem 1 A hot water pipe is used for domestic applications is insulated with a layer of calcium silicate. If the insulation is 25 mm thick and its inner and outer surfaces are maintained at Ts,1 = 800 K and Ts,2 = 400 K, respectively. The outside diameter is 0.12 m. Given the thermal conductivity calcium silicate insulation equals to 0.09 W/m.K. A. Define the difference between lagged and unlagged pipes. B. Calculate the heat loss per unit length for this pipe.arrow_forwardTask 3 Superheated steam at 575°C is routed from a boiler to the turbine of an electric power plant through steel tubes (k = 35 W/m K) of 300 mm inner diameter and 30 mm wall thickness. To reduce heat loss to the surroundings and to maintain a safe-to-touch outer surface temperature, a layer of calcium silicate insulation (k = 0.10 W/m K) is applied to the tubes, while degradation of the insulation is reduced by degradation of the insulation is reduced by wrapping it in a thin sheet of aluminium having an emissivity of = 0.20. The air and wall temperatures of the power plant are 27°C. Assume that the inner surface temperature of a steel tube corresponds to that of the steam and the convection coefficient outside the aluminium sheet is 6 W/m²K, (a) What is the minimum insulation thickness needed to ensure that the temperature of the aluminium does not exceed 50°C? (b) What is the corresponding heat loss per unit meter? (c) What is the difference between lagged and unlagged pipes in…arrow_forwardA single full penetration weld pass is made on a thin steel plate using a power inputof 4 kW, and welding speed 10 mm/s, resulting in a heat transfer efficiency of 85%.The material has a specific heat per unit volume ρc of 0.005 J/mm3-oC and thickness 5 mm. If the ambient temperature is 25 oC, and the melting temperature of the material is 1500 oC .Determine: a) the peak temperature at a distance of 1.0 mm from the weld fusion boundary b) the heat affected zone size.arrow_forward

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning